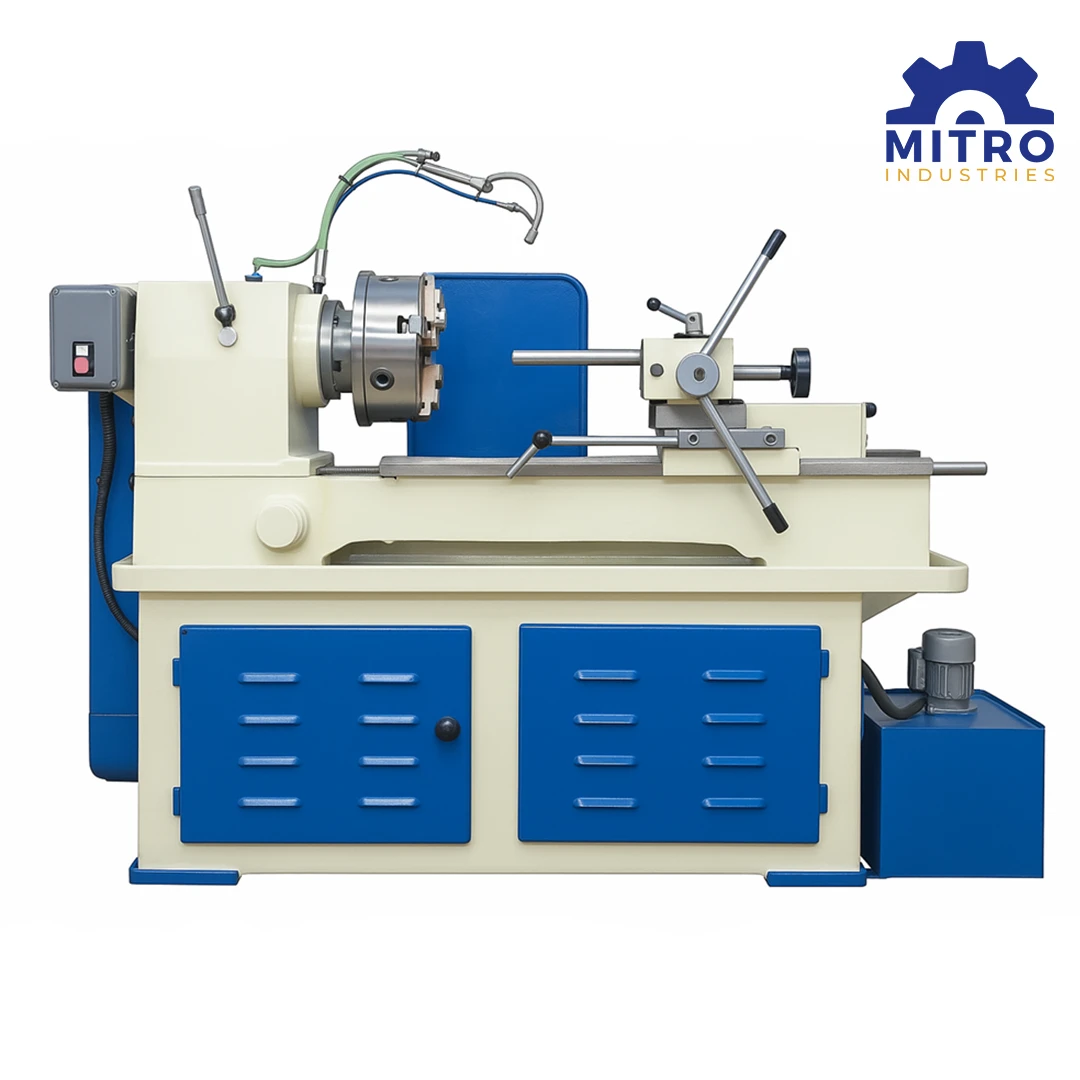

Foundation Bolt Threading Machine

Discover high-performance Foundation Bolt Threading Machines by Mitro Industries. Cut precise threads on round bars & TMT bars using tangential chasers. Ideal for BSP, NPT, BSW, and more thread types. View Complete Details...

₹ 175000/Set

Product Specification

At Mitro Industries, we specialize in manufacturing high-performance Foundation Bolt Threading Machines designed to deliver precision, strength, and efficiency. Our machines are ideal for cutting external threads on a variety of materials, including round bars and TMT bars, using the highly efficient chasing method with tangential chasers.

What is a Foundation Bolt Threading Machine?

A Foundation Bolt Threading Machine is used to cut external threads on bolts or rods, particularly foundation bolts, which are critical in civil and industrial construction. These machines use Tangential Chasers as cutting tools, ensuring clean and accurate thread formation without moving the workpiece. The die head rotates while the job remains stationary, resulting in super-fine, uniform threading.

Key Features & Components

Our machines are engineered with durable, high-quality components to ensure long life, reliability, and ease of use

Base

• The strong base provides foundational stability for the entire machine, ensuring vibration-free operation.

Headstock

• Designed for rigidity and perfect alignment with carriageways.

• Made from shaven alloy steel.

• Shafts are constructed from heat-treated alloy steel for enhanced durability.

Pillar Bed

• Built for user convenience with a rigid yet smooth structure.

• Uses chrome-plated pillars to guide the saddle.

• Includes protective guards to prevent damage.

Saddle

• Precisely mounted on two chrome pillars.

• Smooth, accurate movement ensures consistent alignment with the headstock.

Apron

• Controls the saddle's movement along the pillars.

• Uses a steel rack and high-quality steel gears for reliable transmission.

Bed or Pillar Type Clamping Vice

• Heavy-duty, box-type vice fitted with hardened alloy steel jaws.

• Movement controlled by a screw mechanism for precision gripping.

• Ensures perfect alignment with the headstock center.

Specification

| Length of Bed | 53'' |

| Width of Bed | 12'' |

| Height of Bed | 13'' |

| Length of Pedestal Box | 52'' |

| Width of Pedestal Box | 18'' |

| Height of Pedestal Box | 21'' |

| Length of Slide | 18'' |

| Width of Slide | 12'' |

| Height of Slide | 3'' |

| Length of Head | 15'' |

| Width of Head | 12'' |

| Height of Head | 12'' |

| Threading Length | 32mm - 400mm | 40mm - 300mm | 65mm - 350mm |

| Motor | 3Hp, 5Hp & 7.5Hp (1440 RPM) |

| Power Supply | 415 Volt & 3 Phase Connection |

| Frequency | 50/60 Hz |

| Hardness of Sheet | 60 HRC |

Types of Model

• 8mm - 25mm

• 12mm - 40mm

• 12mm - 65mm

Range of Die Heads Available

Our machines support a wide threading range, with die heads suited for different diameters

Diameter Range | Die Head Size |

| 1/4 inch to 1 inch | Standard |

| 3/8 inch to 1.1/2 inch | Medium |

| 1/2 inch to 2.1/2 inch | Heavy Duty |

| 1 inch to 4 inch | Extra Heavy |

These ranges make our machine perfect for foundation bolt threading, construction rods, and custom applications.

Threading Method - Chasing with Tangential Chasers

The chasing method allows fast and precise threading using Tangential Chasers, which can be changed based on the thread type and pitch. This method ensures

• High-speed threading

• Clean thread finish

• Long chaser life

• Accurate thread profiles

Supported Thread Types

The Foundation Bolt Threading Machine by Mitro Industries is capable of cutting a wide range of thread profiles, including

• BSP (British Standard Pipe)

• BSPT (British Standard Pipe Tapered)

• NPT (National Pipe Thread)

• BSW (British Standard Whitworth)

• UNF (Unified National Fine)

• UNC (Unified National Coarse)

• MATRIX Threads

• Acme Threads

Applications

The Foundation Bolt Threading Machine by Mitro Industries is ideal for

• Construction Sites

• Infrastructure Projects

• Steel Fabrication Units

• Manufacturing of Foundation Bolts, Anchor Bolts, and Threaded Bars

Whether you’re working with round bars or TMT bars, this machine can cut clean threads with consistent quality.

Why Choose Mitro Industries?

• Precision-built machines with low maintenance

• Custom solutions for client-specific threading needs

• Nationwide service and support

• Trusted by leading construction and engineering firms

Product related to Construction Machine

Find a similar products you may like