Rebar Cold Forging Machine

The Rebar Cold Forging Machine is a specialized piece of equipment designed for reinforcing bar (rebar) processing in the construction industry. View Complete Details...

₹ 260000/Set

Product Specification

Rebar Cold Forging Machine is engineered for precision and durability, this machine increases the diameter of rebar ends by cold forging, allowing for superior threading and mechanical splicing. Ideal for large-scale infrastructure and high-rise projects, our system delivers consistent results with minimal material waste and labor input. Easy to operate, energy-efficient, and built to last — the Rebar Cold Forging Machine is the reliable solution for modern rebar processing. This technique is widely used to ensure strong, secure, and reliable connections in reinforced concrete structures.

How It Works

The cold forging machine applies high-pressure force to the end of a rebar, increasing its diameter without the use of heat. This mechanical deformation improves the density and structural integrity of the steel, making it suitable for subsequent threading or coupler-based joining systems.

Key Features

• High Precision Output - Consistent forging quality that meets international construction standards.

• Energy Efficient - Operates without requiring heat, reducing power consumption.

• Strong Splice Preparation - Enhances tensile strength and bonding for mechanical couplers.

• Easy Operation - Simple control interface, suitable for both skilled and semi-skilled workers.

• Robust Construction - Heavy-duty design ensures long service life, even under continuous operation.

Specification

• Capacity - 16mm to 40mm

• Application - To forged the end of the TMT Bar

• Motor Power - 5 Hp for 32mm Bar & 7.5 Hp for 40mm Bar

• Power Supply - 3 Phase Connect with 415 Volts

• Power Frequency - 50/60 Hz

• Pressure - 4000 PSI & 275.8 Bar

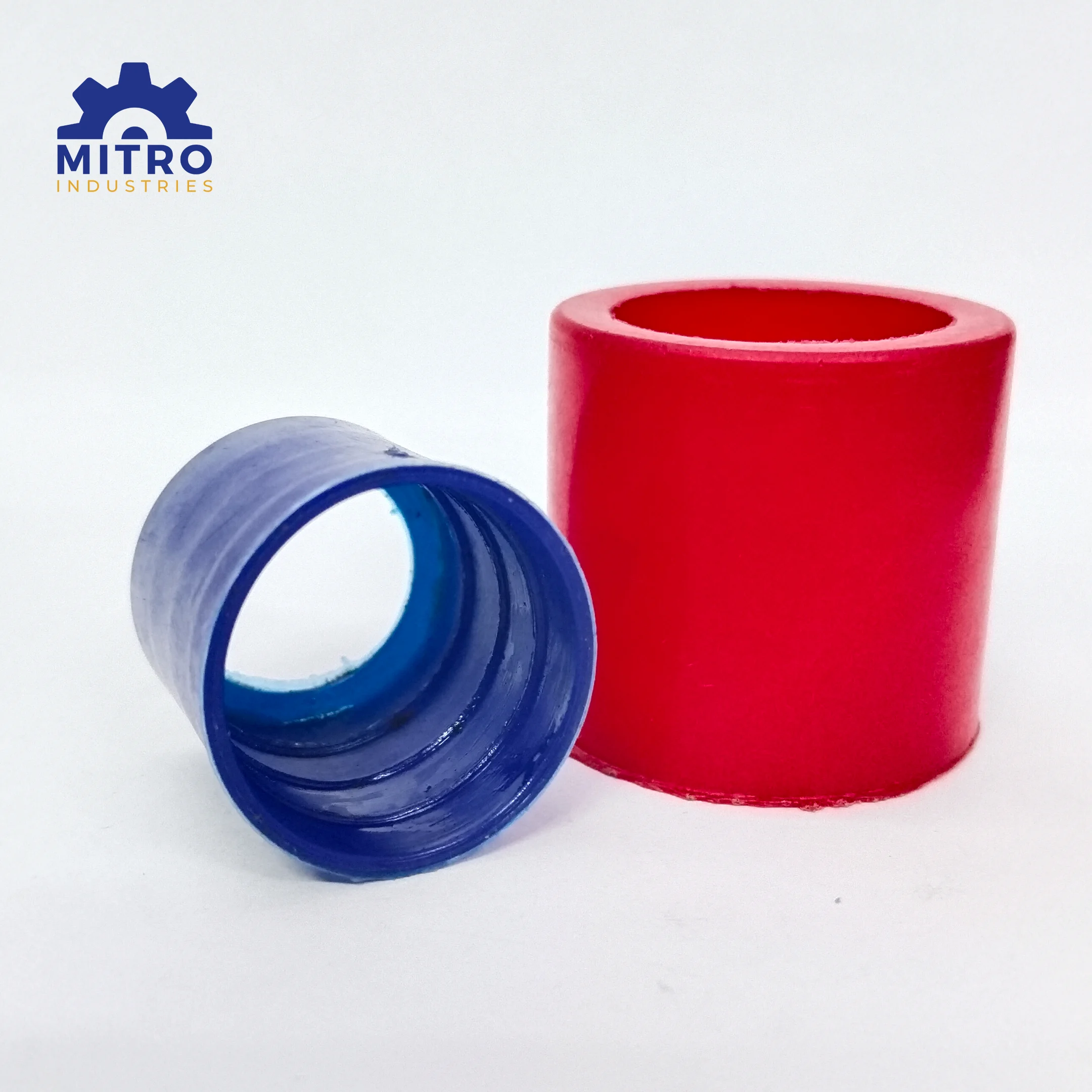

• Hydraulic System - Poly Ukan Hydra

• Material - EN31, SS, MS

• Automation - Semi Automatic

• Tank Capacity - 150 Ltr for 32mm & 180 Ltr for 40mm

• Weight - 1100 Kg

Applications

• Skyscraper and high-rise construction

• Bridge and highway infrastructure

• Industrial building frameworks

• Precast concrete facilities

• Seismic retrofitting projects

Advantages

• Improved safety and strength at rebar joints

• Time and labor savings compared to traditional welding or lap splicing

• Minimizes rebar waste and material costs

• Facilitates faster construction timelines

At Mitro Industries, we manufacture and supply highly efficient Rebar Cold Forging Machines designed to create a bulged end on TMT bars before the threading operation. These machines are essential in reinforcing bar connection systems and play a crucial role in achieving strong mechanical joints.

Product related to Construction Machine

Find a similar products you may like