Why bubble cap tray used in distillation column?

05 Aug 2025

Oil and Gas

2549

"Bubble cap trays are used in distillation columns to enhance the interaction between vapor and liquid phases, crucial for separating components with different boiling points."

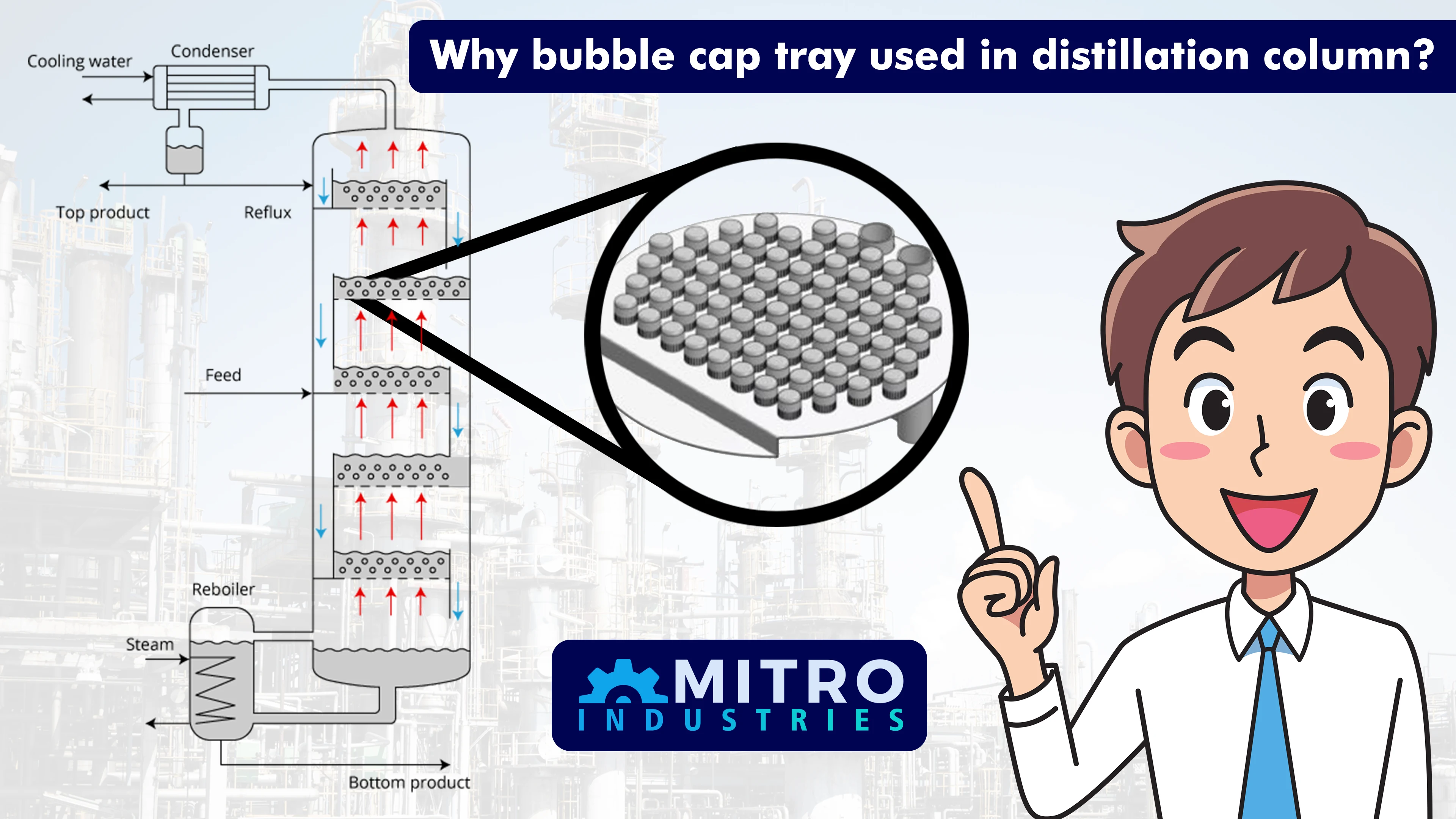

Bubble cap trays are used in distillation columns to enhance the interaction between vapor and liquid phases, crucial for separating components with different boiling points. They achieve this by dispersing vapor through liquid, creating a large surface area for mass transfer, which leads to more efficient separation.

Vapor-Liquid Contact

Bubble cap trays are designed with a perforated plate and bubble caps, which are essentially caps placed over the perforations. Vapor rises through the slots or chimneys beneath the caps and is then forced to bubble through the liquid layer on the tray.

Enhanced Mass Transfer

This bubbling action creates a large surface area for vapor-liquid contact, promoting the transfer of components between the phases. More volatile components will vaporize and transfer to the vapor phase, while less volatile components will condense and transfer to the liquid phase.

Effective Separation

By maximizing vapor-liquid contact, bubble cap trays ensure efficient separation of the mixture's components based on their volatility.

Wide Range of Applications

They are commonly used in various industries like chemical, petrochemical, and refining, especially where low flow rates or fouling conditions are present.

Specific advantages

Bubble cap trays can be designed for minimal leakage, low liquid loads, and have a high turndown ratio (ability to operate effectively at varying flow rates), according to Kuber Internals.

In essence, bubble cap trays are a reliable and effective solution for distillation columns needing precise control and efficient separation, particularly in challenging operating conditions.

Popular Posts

-

Why Backer Rod Is Used in Road Construction?

2687 Views