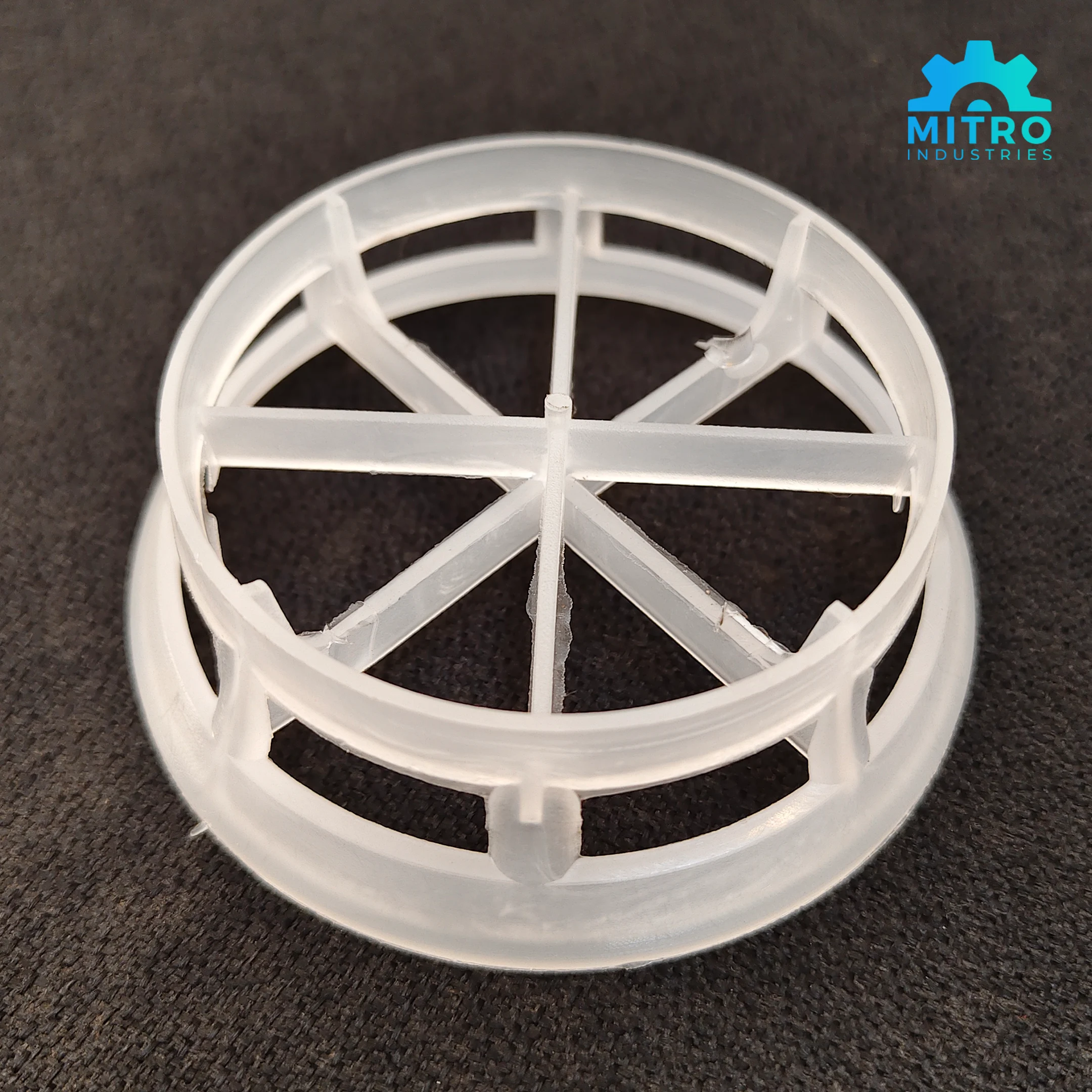

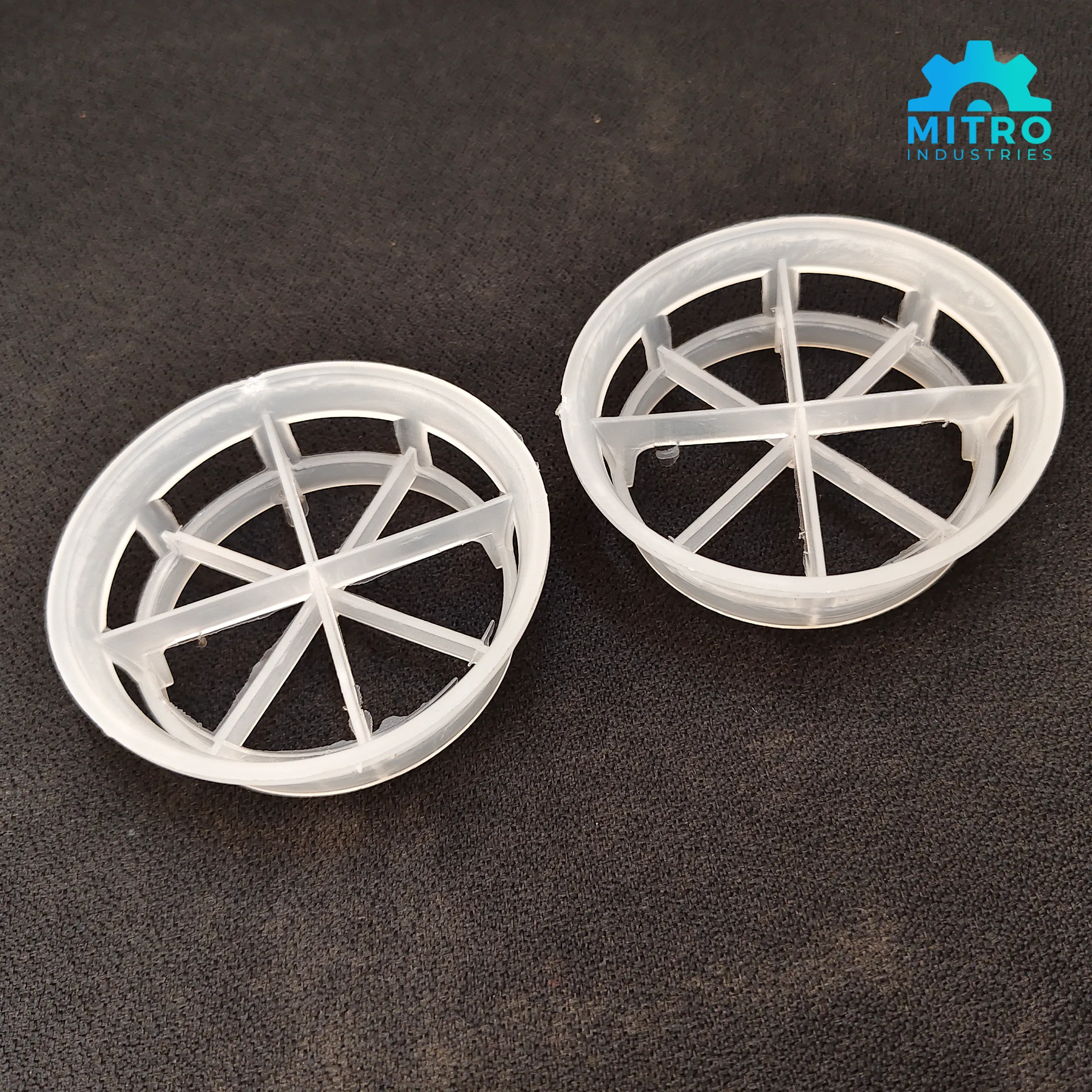

PP Cascade Mini Ring

Buy high-quality PP Cascade Mini Rings for scrubbers, distillation columns, and gas-liquid separation. Learn about features, benefits, applications, and technical advantages of Polypropylene Cascade Mini Rings. View Complete Details...

Product Specification

PP Cascade Mini Rings are advanced plastic random packing elements designed to deliver superior gas–liquid contact efficiency in industrial towers. Made from high-quality Polypropylene (PP), these mini rings are engineered to provide low pressure drop, high mass transfer rates, and excellent mechanical strength—making them ideal for chemical processing, gas scrubbing, wastewater treatment, and other mass-transfer operations.

What is a PP Cascade Mini Ring?

A PP Cascade Mini Ring is a modern variation of traditional random packing. Its open structure and unique geometry enhance surface area and improve gas–liquid distribution. Unlike saddles or Pall Rings, Cascade Mini Rings reduce the risk of fouling and offer higher hydraulic capacity.

Key Features

• High void fraction for reduced pressure drop

• Excellent chemical resistance due to polypropylene construction

• Improved liquid hold-up for higher mass-transfer efficiency

• Low fouling design with smooth surfaces

• UV-stabilized and corrosion-resistant material

• Lightweight with easy installation

Technical Advantages

• Enhanced mass-transfer efficiency compared to saddles and conventional rings

• Better gas–liquid distribution due to optimized geometry

• High durability in corrosive and harsh environments

• Low maintenance cost and long service life

Applications of PP Cascade Mini Rings

• PP Cascade Mini Rings are widely used across multiple industries, including:

• Scrubbers & Absorbers

• Stripping Columns

• Distillation Towers

• Air Pollution Control Systems

• Water & Wastewater Treatment Plants

• Chemical Processing Industries

• Desulfurization Plants

Why Choose PP Cascade Mini Rings?

These mini rings outperform traditional plastic random packing due to

• Better performance under high-load operations

• Superior wetting characteristics

• Cost-effective packing material for towers and reactors

• Versatile compatibility with corrosive gases and liquids

If you are looking for reliable, high-performance plastic random packing, PP Cascade Mini Rings are an excellent choice to optimize your mass-transfer process.

Product related to Tower Packing

Find a similar products you may like