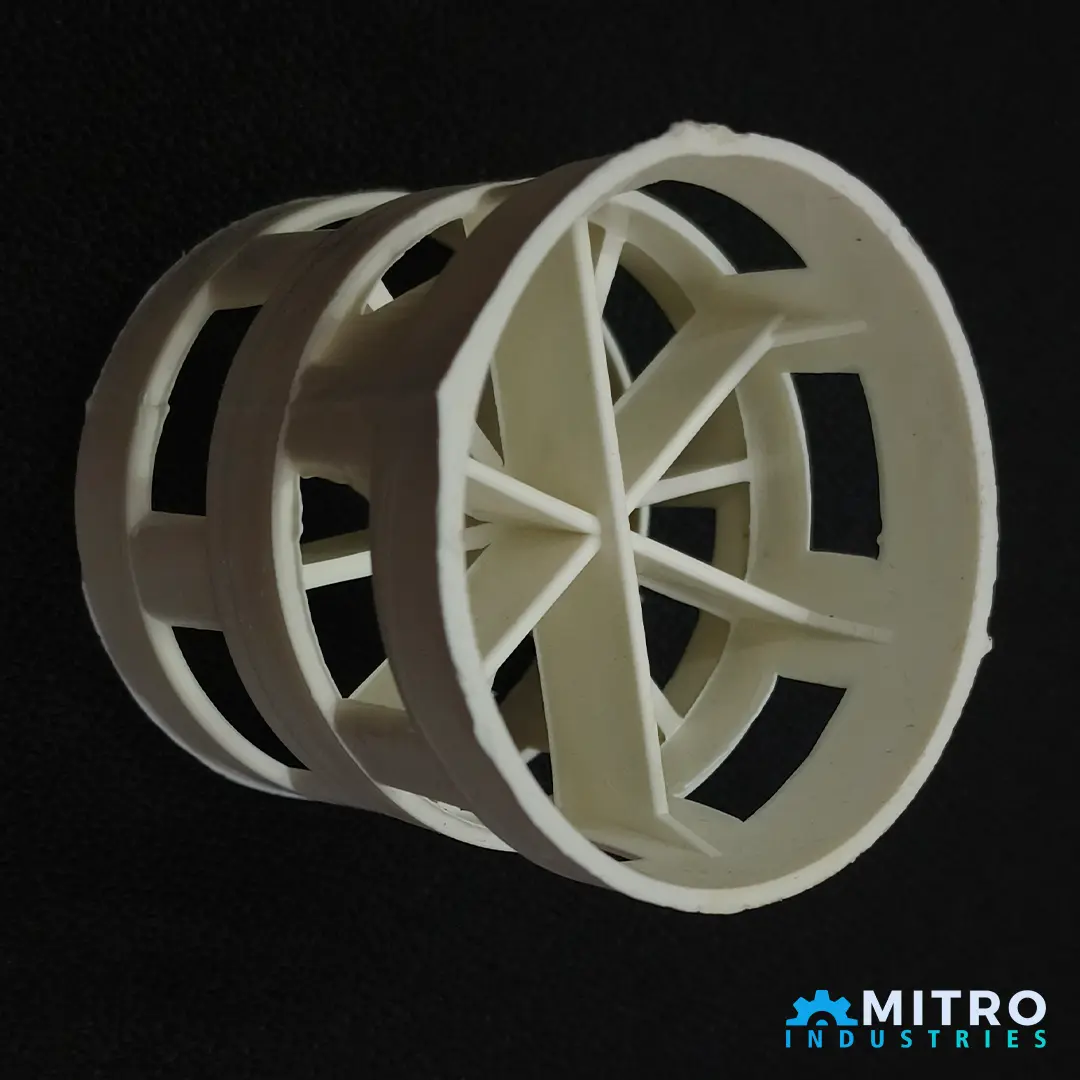

SS Pall Ring

We are leading Manufacturer of Pall Ring in India. Pall ring is one of the most common and well-known packing materials, SS Pall Ring is an industry-standard design media and is used widely in a variety of applications. View Complete Details...

Product Specification

Pall ring is one of the most common and well-known packing materials, SS Pall Ring is an industry-standard design media and is used widely in a variety of applications. By minimizing the number of contours and crevices that can cause liquid hold-up and potential entrainment, the SS pall ring geometry enables high gas and liquid transfer rates. The opened cylinder walls and inward bent protrusions of the SS pall Ring allow greater capacity and lower pressure drop than standard cylindrical rings. Mitro Pall ring design also maintains an even distribution and resists wall-channeling tendency. The interior and exterior contacting surfaces of the SS pall ring provide for the effective distribution of liquids and gasses and resist plugging, fouling and nesting. Mitro Pall rings are available in a wide range of materials.

Pall Ring Features

1. Capacity vs Pressure Drop of SS Pall Ring Packing, High loading & throughput / low-pressure drop, Good liquid/gas distribution and high mass transfer efficiency.

2. Versatility, Easily wettable, High resistance to fouling, High Temperature.

3. Mechanical Strength of SS Pall Ring Packing, High-temperature applications, Mechanically robust, lesser probability of breakage, suitable for deeper beds.

Pall Ring Application

SS Pall Ring Packing is widely used in All kinds of separation, absorb plants, constant decompress plants, compounding ammonia plants, decarbonization, desulfuration separation of ethylbenzene, separation of isooctane/ methylbenzene, Absorption, Aeration, Degassing, Desorption, Distillation, Stripping, Heat Recovery, Extraction, Various separation and absorption applications at atmospheric pressure and under vacuum, where a low-pressure drop is critical, H2S, NH3 & SO2 Absorption & Stripping, Steam Stripping, Quench towers, Direct contact cooling.

Mitro Pall Ring deserve your choice.

If any interest or demand, please free to contact us. More information will sent on request.

Call or Whatsapp Us on +91 7400422366

Email Us on mitroindustries@gmail.com

SS Pall Ring Sizes

| Sizes | Thickness | Nos/m3 |

|---|---|---|

| 16 mm | 0.3 mm | 220000 |

| 25 mm | 0.4 mm | 52000 |

| 38 mm | 0.5 mm | 13500 |

| 50 mm | 0.6 mm | 6500 |

| 75 mm | 0.8 mm | 1900 |

Product related to Tower Packing

Find a similar products you may like