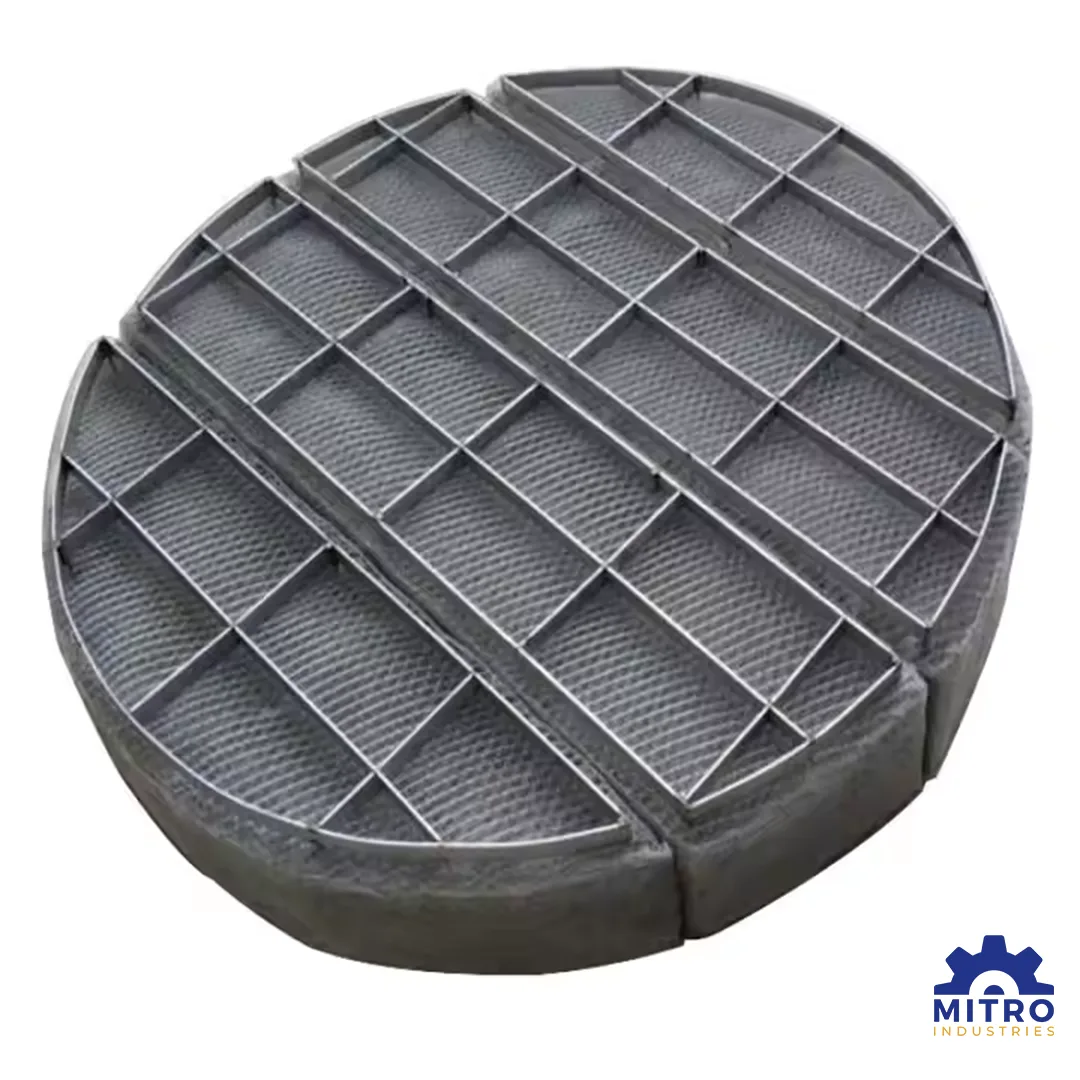

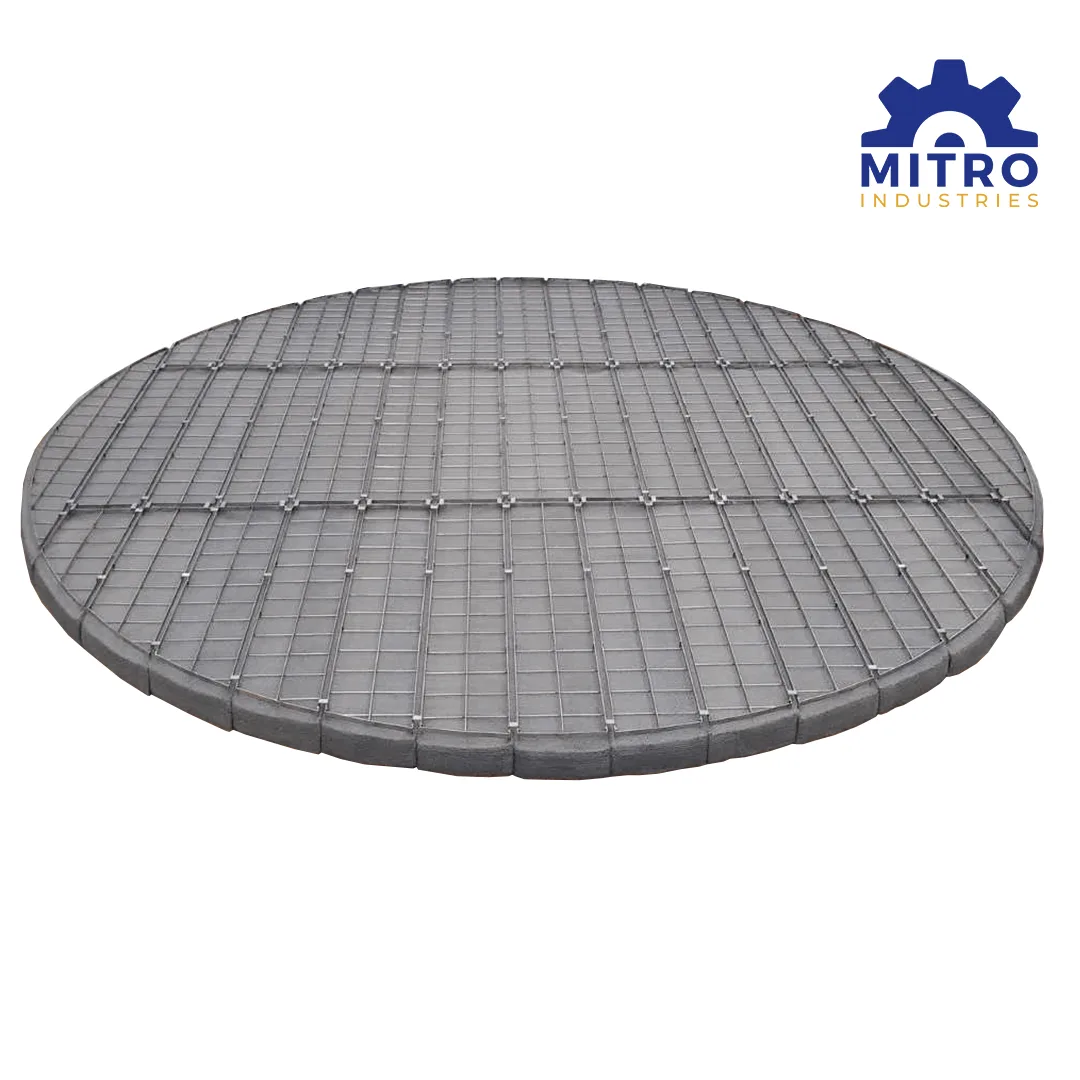

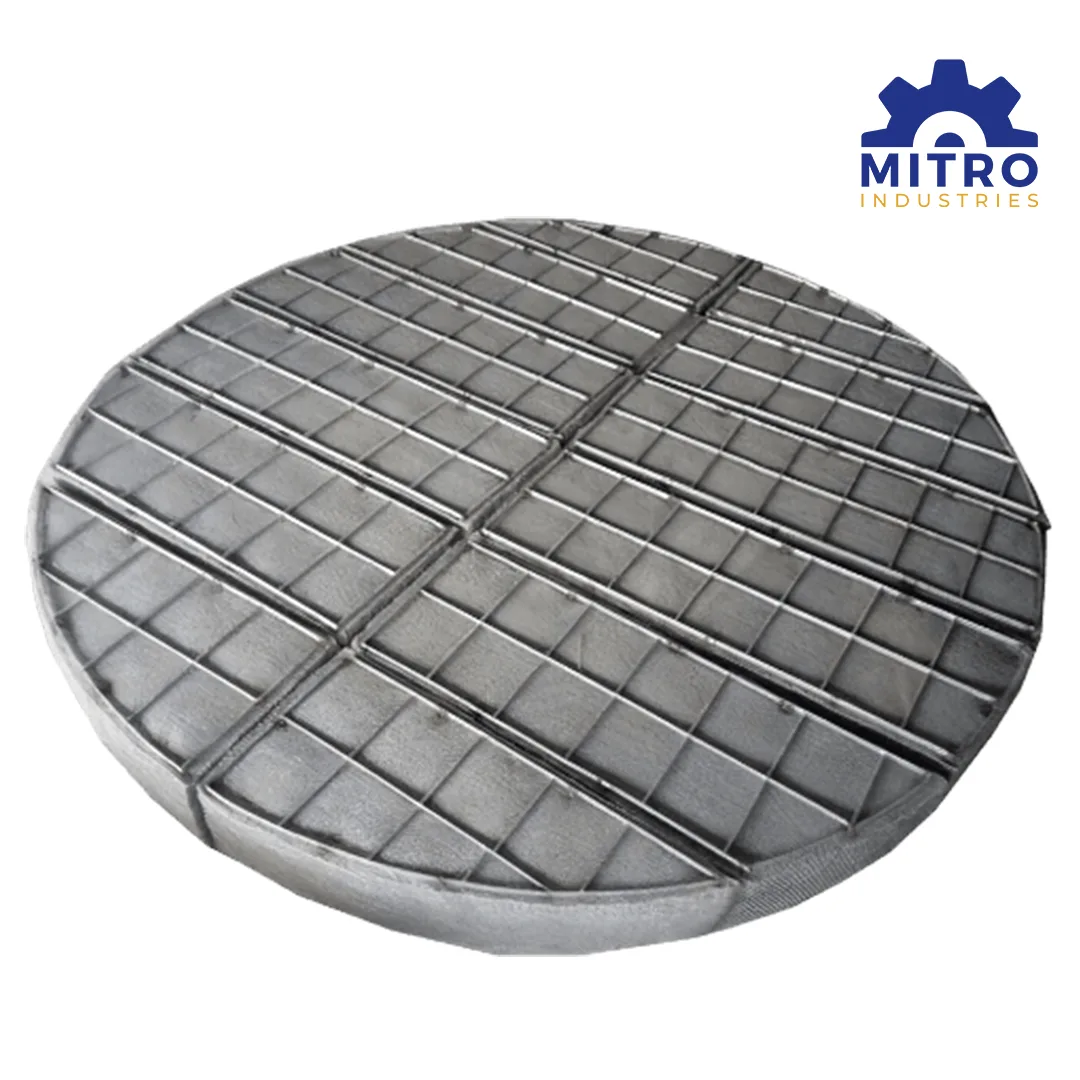

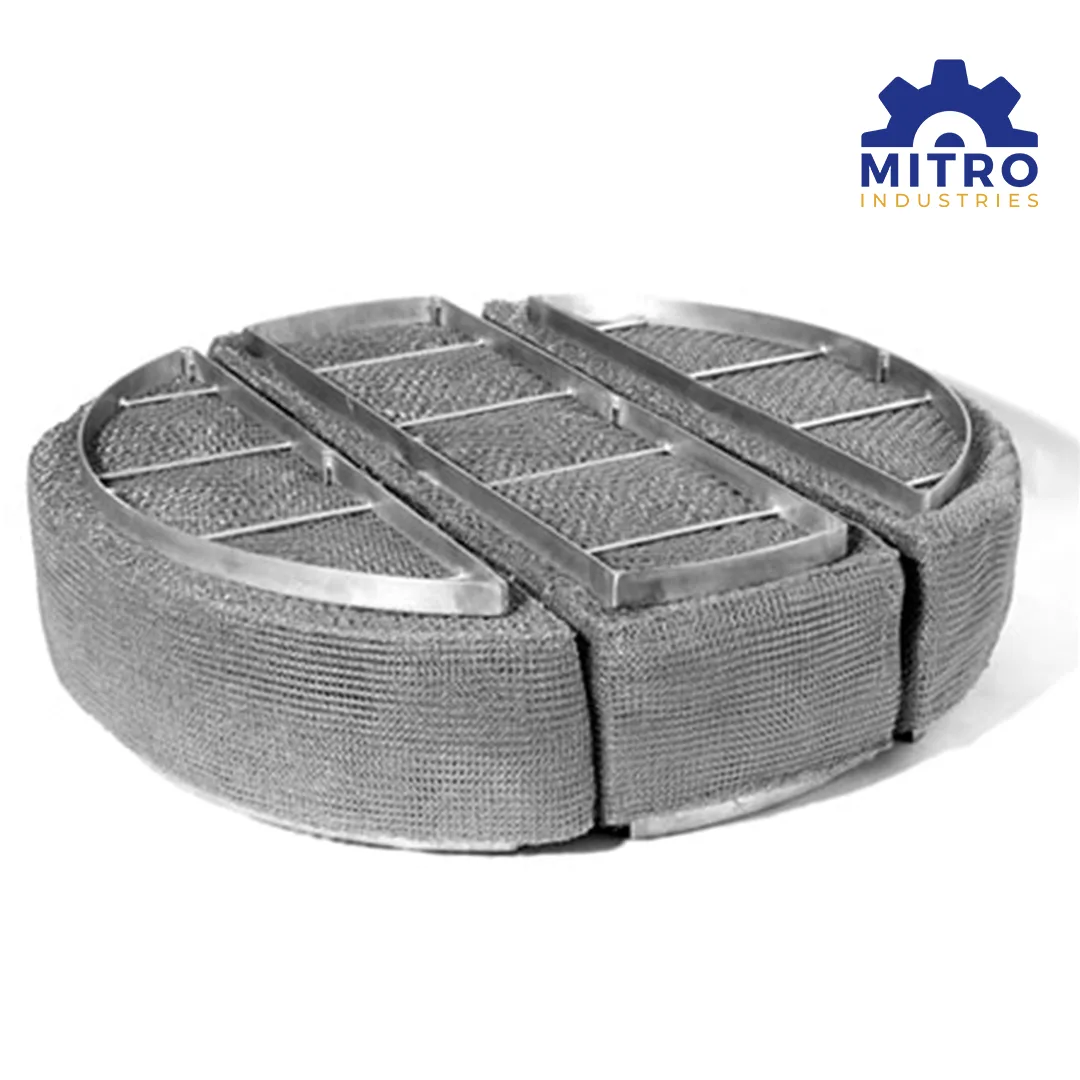

SS Demister Pad

Stainless steel demister pads offer high corrosion resistance, excellent separation efficiency, and durability in high-temperature environments. View Complete Details...

Product Specification

Stainless steel demister pads are widely recognized for their exceptional resistance to corrosion and rust, making them a preferred choice for demanding industrial applications. Along with excellent chemical stability, these demister pads deliver high separation efficiency and outstanding temperature resistance. Among all metal mist eliminators, stainless steel demister pads are the most commonly used due to their versatility and durability.

Stainless steel materials vary in composition, which allows for tailored performance depending on the specific industrial environment. Below are the main types of stainless steel used in demister pads

Types of Stainless Steel Used in Demister Pads

304 Stainless Steel

Manufactured according to ASTM standards, SS 304 contains approximately 19% chromium and 9% nickel. It is the most widely used stainless steel for heat-resistant and general-purpose applications. Known for its excellent corrosion resistance and formability, 304 demister pads are commonly found in process equipment and are safe for use in food production where gas-liquid separation is required.

304L Stainless Steel

A low-carbon version of 304, SS 304L is designed to minimize carbide precipitation, especially in the heat-affected zones near welds. This makes it highly suitable for welding applications, helping prevent intergranular corrosion during fabrication and use.

321 Stainless Steel

SS 321 offers superior high-temperature stress rupture and creep resistance compared to 304. It performs well across a range of organic and inorganic acids, particularly in oxidizing environments, and is widely used in acid containers, wear-resistant equipment, and piping systems. It's an ideal material for industries like chemical processing, petroleum, and coal, where high temperature and corrosion resistance are critical.

316L Stainless Steel

Known for its molybdenum content, SS 316L offers enhanced pitting resistance and high-temperature strength compared to 304 and 310. It is especially effective in acidic environments, including sulfuric acid concentrations below 15% and above 85%. Its superior durability makes it suitable for chemical processing, marine, and food industry applications.

310 Stainless Steel

SS 310 is a high-performance austenitic stainless steel with high chromium and nickel content, offering excellent oxidation resistance, corrosion resistance, and high-temperature strength. It is ideal for applications involving extreme heat and aggressive chemical environments.

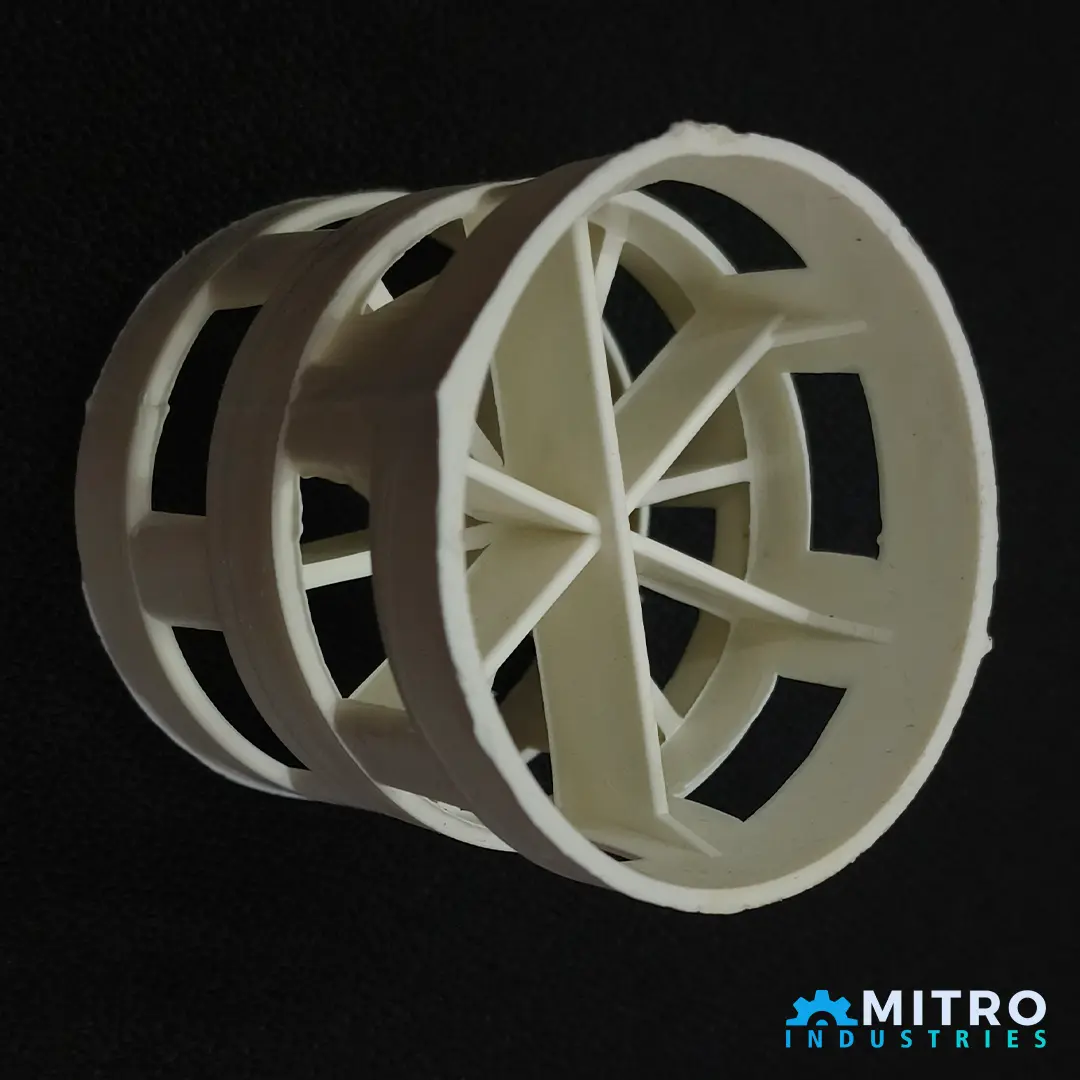

Demister Pad Types and Customization

Stainless steel demister pads can be customized into various shapes and configurations to meet specific equipment and process needs

• Standard Shapes : Round, rectangular, ring, and custom-cut shapes

• Drawer Type : Easy to install and transport

• Wavelike Type : Offers increased surface area for improved separation efficiency

Key Features

• Excellent corrosion and rust resistance

• Resistant to acids, alkalis, and salt-laden environments

• High mechanical strength and thermal durability

• Superior gas-liquid separation efficiency

• Long-lasting and low maintenance

• Available in various configurations

• Easy to install and handle

Applications

Stainless steel demister pads are extensively used across a wide range of industries

• Chemical processing

• Pharmaceutical manufacturing

• Petroleum refining

• Coal mining

• Pulp and paper industry

• Food and beverage processing

Common Specifications

• 442 mm diameter × 150 mm thickness

• 2290 mm diameter × 100 mm thickness

• 11-1/4" width × 1" thickness × 118" length

• 11-7/8" width × 1" thickness × 142" length

• 14-5/6" width × 1" thickness × 142" length

Product related to Tower Packing

Find a similar products you may like