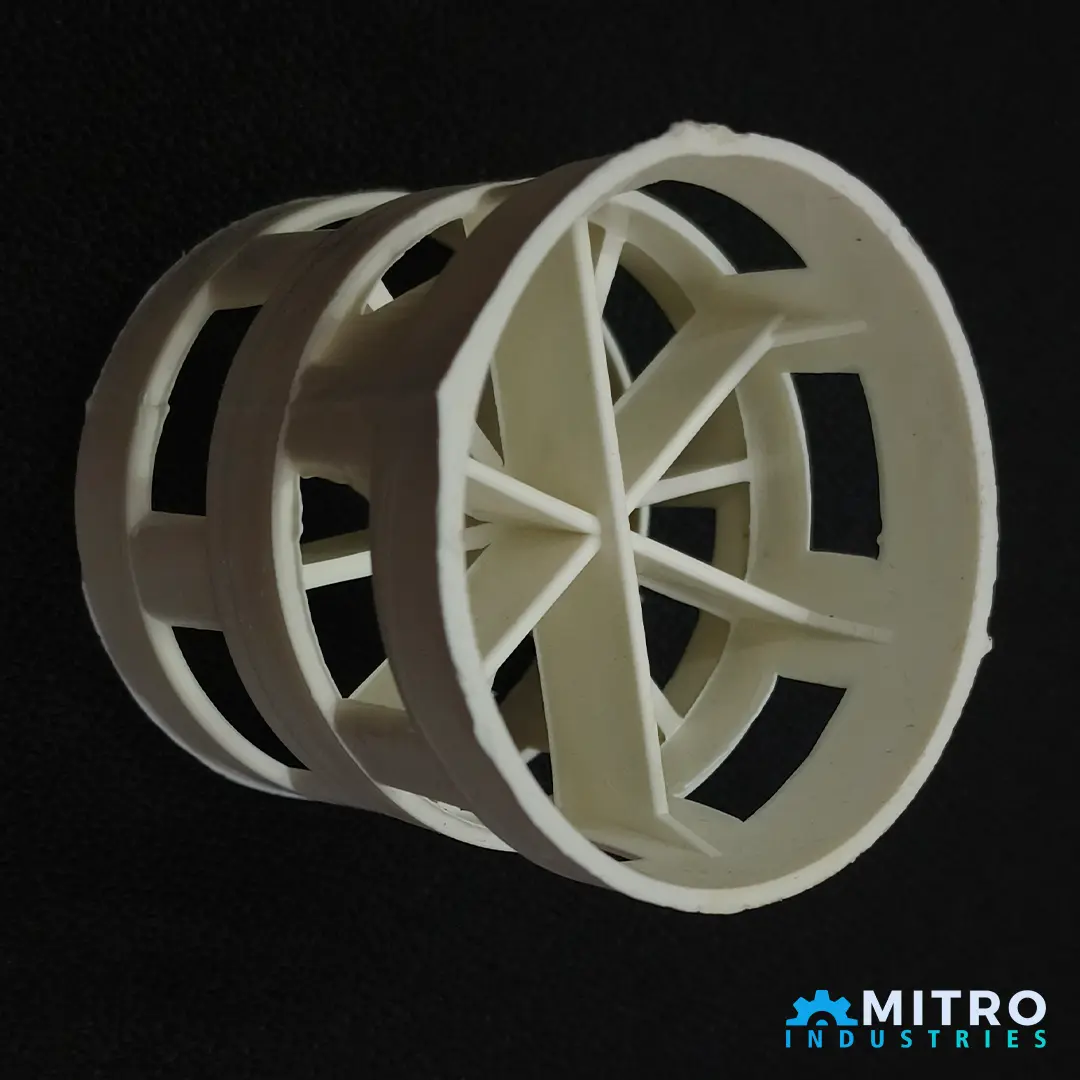

Alumina Ceramic Balls

Ceramic balls are commonly used as tower packing material in chemical processing industries. View Complete Details...

Product Specification

Ceramic Balls serve as support media in packed towers, reactors, and other processing vessels. Ceramic balls are made from inert ceramics, typically alumina or silica-based materials, and offer excellent mechanical strength, thermal resistance, and chemical stability.

Functions of Ceramic Balls in Tower Packing

1. Support Media

Ceramic balls are often placed at the bottom of packed columns to support structured or random tower packing.

They provide a stable bed that prevents smaller packing materials from being washed out or damaged.

2. Flow Distribution

The uniform shape and size distribution help improve the flow of liquids and gases through the tower.

They minimize pressure drop and ensure even distribution of reactants.

3. Thermal and Mechanical Buffer

Ceramic balls resist high temperatures and thermal shock, making them ideal for applications involving hot gases or liquids.

Their strength also supports heavy loads without deformation or breakage.

Sizes of Ceramic Balls

| Size | Kg/Particle | KN/Particle |

| 1/8" (3mm) | >35 | >0.35 |

| 1/4" (6mm) | >60 | >0.60 |

| 3/8" (10mm) | >85 | >0.85 |

| 1/2" (13mm) | >185 | >1.85 |

| 3/4" (19mm) | >487 | >4.87 |

| 1" (25mm) | >850 | >8.50 |

| 1-1/2" (38mm) | >1200 | >12 |

| 2" (50mm) | >5600 | >56 |

Tolerance of Ceramic Balls

| Sizes | 3/6/9 mm | 9/13 mm | 19/25/38 mm | 50 mm |

| Tolerance | ± 1.0 mm | ± 1.5 mm | ± 2 mm | ± 2.5 mm |

Types of Ceramic Balls

1. Inert Ceramic Balls

• Made of materials like porcelain or 99% alumina.

• Used mainly for mechanical support and flow regulation.

2. Catalyst Support Balls

• May be impregnated or coated with catalytic materials.

• Used in processes like reforming, hydrogenation, or desulfurization.

3. High-Alumina Balls

• Offer enhanced resistance to acid and alkali corrosion.

• Suitable for more aggressive chemical environments.

Advantages of Ceramic Balls

• Chemical Inertness - Resist most acids, alkalis, and organic solvents.

• Thermal Stability - Operate at temperatures up to 1000°C or more.

• Durability - Low attrition rate and long service life.

• High Porosity (optional) - Some variants can be manufactured with porous structures to enhance gas/liquid contact.

Common Applications

• Petrochemical Processing

• Natural Gas Treatment

• Sulfur Recovery Units

• Fertilizer Production

• Pharmaceutical and Food Processing Industries

Selection Criteria

When choosing ceramic balls for tower packing, consider

• Operating Temperature and Pressure

• Chemical Composition of Process Fluids

• Packing Bed Depth and Load

• Required Void Space and Flow Characteristics

Ceramic balls are an essential component in packed tower systems, offering mechanical support, chemical resistance, and efficient fluid distribution. Their versatility and robustness make them a staple in various industrial applications.

Product related to Tower Packing

Find a similar products you may like