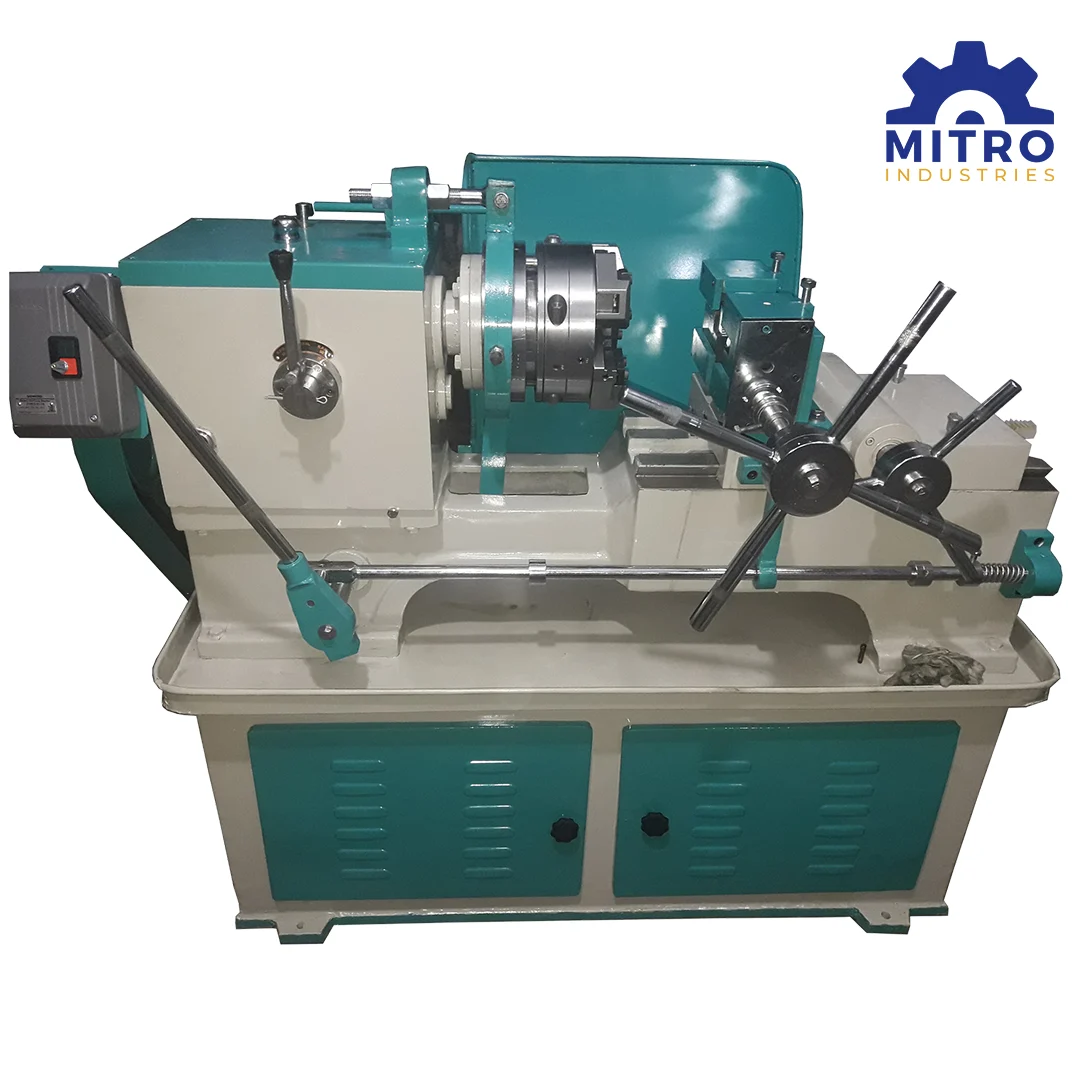

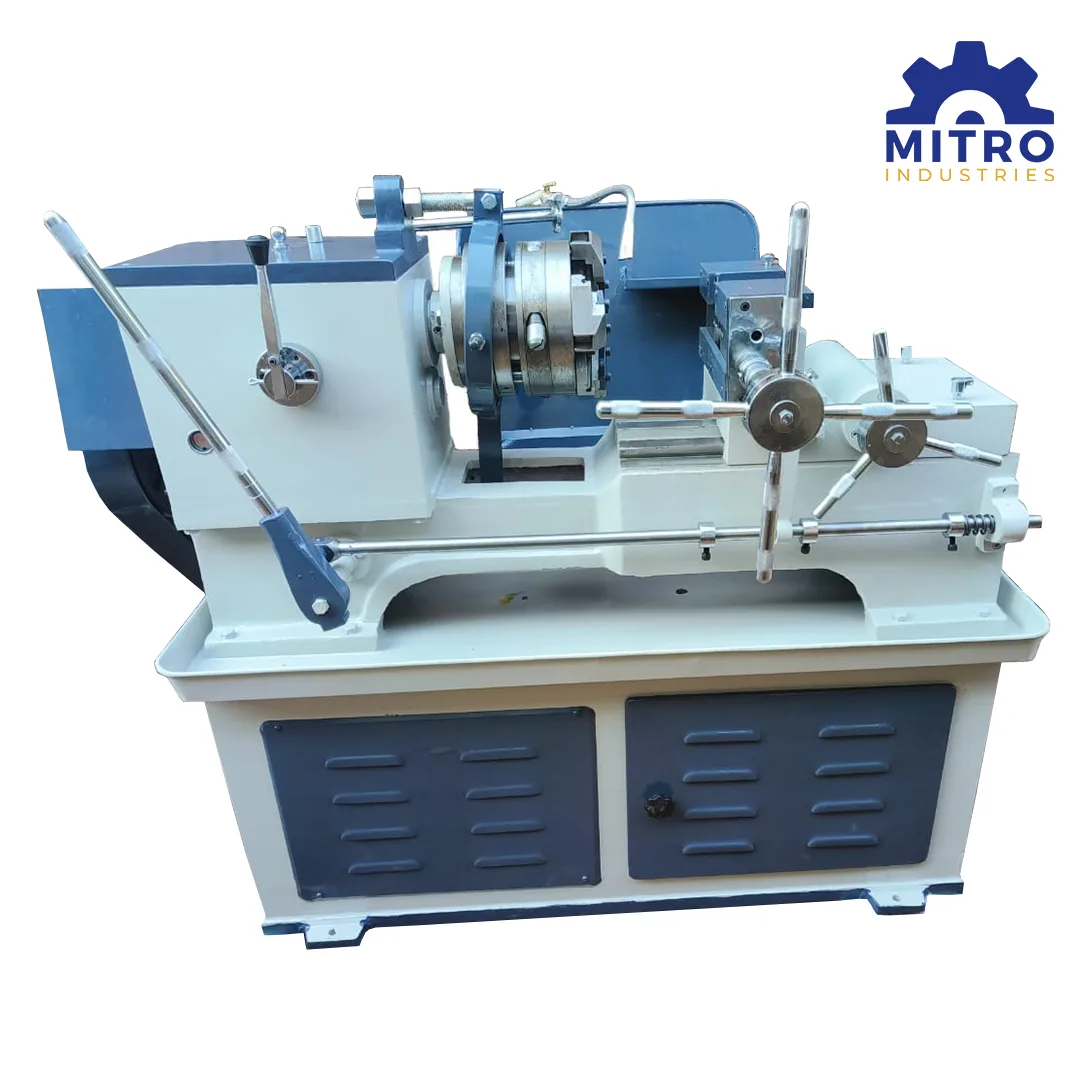

Lanco Die Head Chaser Threading Machine

High-performance lanco die head chaser threading machine with tangential chasers for cutting BSPT, NPT, Metric, and more. Durable, precise, and ideal for industrial use. View Complete Details...

Product Specification

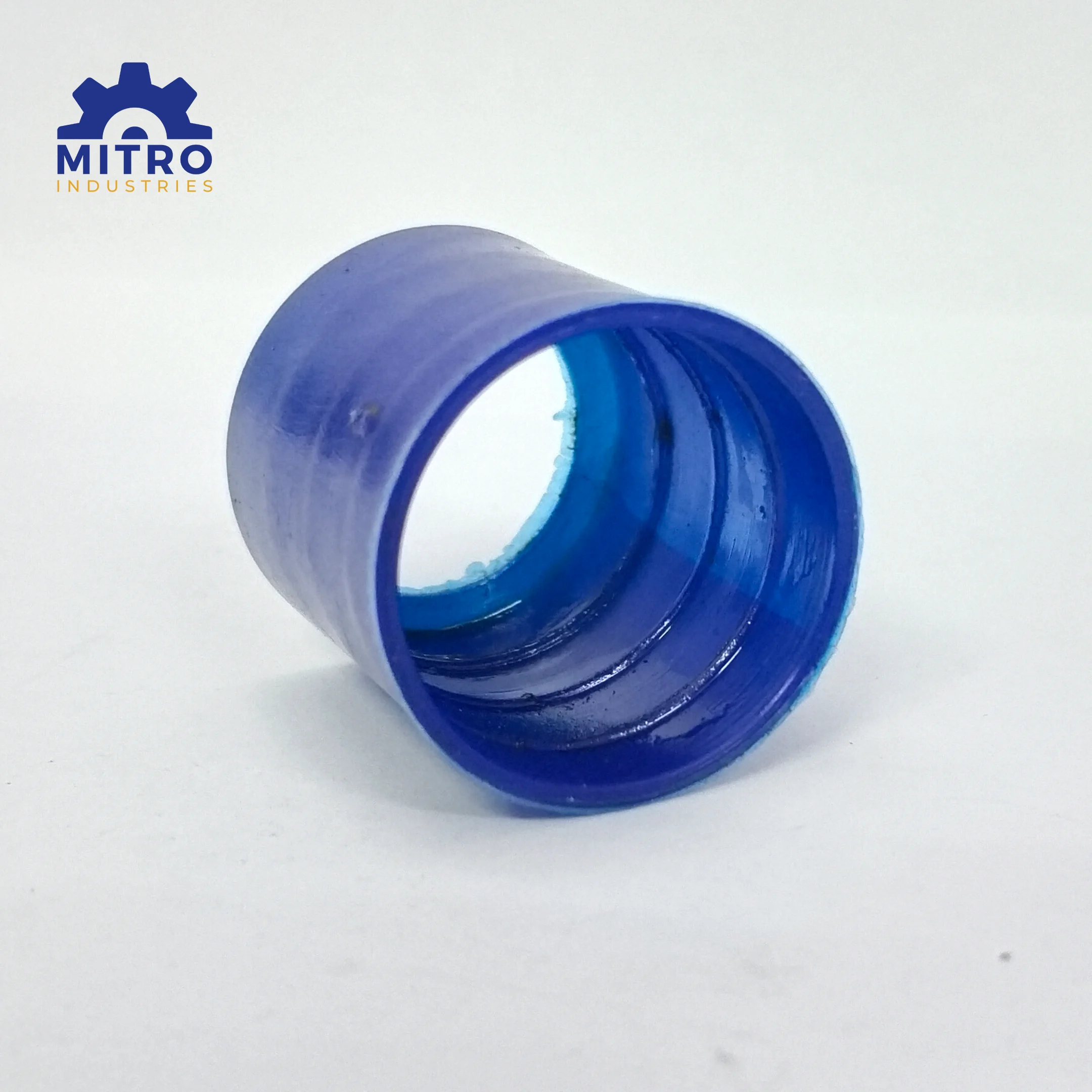

The Lanco Die Head Chaser Threading Machine is a high-precision industrial machine used for cutting external threads with the help of Tangential Chasers. These chasers function as cutting tools in the threading process. In this setup, the bolt remains stationary, while the die-head rotates, allowing for precise cutting of parallel and taper threads. This includes various thread types such as

• BSPT (British Standard Pipe Taper)

• BSW (British Standard Whitworth)

• BSP (British Standard Pipe)

• NPT (National Pipe Tapered)

• UNF (Unified Fine Thread)

• Metric Threads

• UNC (Unified Coarse Thread)

• ACME Threads

• BSF (British Standard Fine)

Specification

| Length of Bed | 53'' |

| Width of Bed | 12'' |

| Height of Bed | 13'' |

| Length of Pedestal Box | 52'' |

| Width of Pedestal Box | 18'' |

| Height of Pedestal Box | 21'' |

| Length of Slide | 18'' |

| Width of Slide | 12'' |

| Height of Slide | 3'' |

| Length of Head | 15'' |

| Width of Head | 12'' |

| Height of Head | 12'' |

| Threading Length | Upto 32mm - 400mm / Upto 40mm - 200mm |

| Motor | 3Hp & 5Hp (1440 RPM) |

| Power Supply | 415 Volt & 3 Phase Connection |

| Frequency | 50/60 Hz |

| Hardness of Sheet | 60 HRC |

Key Features of Lanco Die Head Chaser Threading Machines

Mitro Industries designs its Lanco Die Head Chaser Threading Machines to deliver maximum efficiency, high accuracy, and reliable performance, even under the most demanding industrial conditions. The machines are engineered to reduce maintenance needs while offering consistent output.

• The Spindle bore 38mm Fitted with Tapper Bearing 32210 & 32211.

• The machine has Two Speeds 60 & 90 RPM.

• All Gears are Tempered (Oil Seals 45 x 65 x 10).

• Motor Pully 12'' Dia, V-Belt Drive Vice Fitted with Jaw.

High-Quality Gears

All gears are crafted from case-hardened steel, with extra-large face width and thicker teeth, cut on advanced hobbing machines to ensure quiet operation even at high speeds.

Precision Engineering & Durability

Built to uphold the highest standards of workmanship, material quality, and engineering tradition, our threading machines are ideal for industries that demand precision and durability.

Machine Construction Details

Head Stock

• Built with heavy-duty geared head box

• Made from premium quality casting

• Supports spindle bearings with three extra heavy-duty bearings

• Fully lubricated gear system for long-lasting performance

Machine Bed

• Pillar-type design with two chrome-plated steel pillars

• Pillars are hard chrome plated in a state-of-the-art plating unit

• Ensures stability and smooth operation

Saddle

• Mounted precisely on the pillars

• Ensures smooth and accurate travel aligned with the head stock

• Designed for optimal rigidity and alignment

Apron

• Provides saddle movement along the pillars

• Operates via steel rack and pinion mechanism

• All gears are manufactured from premium quality steel

Vice Jaws

• Made from alloy steel, heat-treated for durability

• Fitted into a heavy-duty box-type vice

• Precisely aligned with the head stock center

• Movements controlled by a screw mechanism on the saddle

Why Choose Our Lanco Die Head Chaser Threading Machines?

• Robust Construction for Industrial Use

• Precision Threading for a Wide Range of Thread Types

• Low Maintenance & Long Service Life

• Smooth & Noiseless Operation

• Backed by Company Tradition of Quality

Applications

Our Lanco Die Head chaser threading machines are widely used in industries such as

• Oil & Gas

• Plumbing

• Construction

• Automotive

• Heavy Engineering

Product related to Rebar Threading Machine

Find a similar products you may like

Product Rating & Review

Frequently Asked Question

These include

• Increased Strength and Durability

• Faster and More Efficient

• Improved Precision

• Reduced Material Waste

• Better Quality Control

• Threading Inconsistencies

• Power Failures

• Overheating

• Lubrication

• Inspection of Dies

• Checking for Leaks

• Calibration

• Railways

• highways

• construction of bridges

• Dams

• Power Plants

• Metro

• Railway Tunnels

• Precast Concrete Construction

• Improved efficiency and speed in threading rebar.

• Accurate and uniform threads for secure connections.

• Reduction in manual labour and associated risks.

• Higher quality of construction due to consistent threading.

• Regularly clean the threading head and dies to remove debris and dust.

• Lubricate moving parts to prevent wear and tear.

• Check for worn-out parts and replace them as necessary.

• Ensure proper alignment of the rebar to avoid uneven threading.