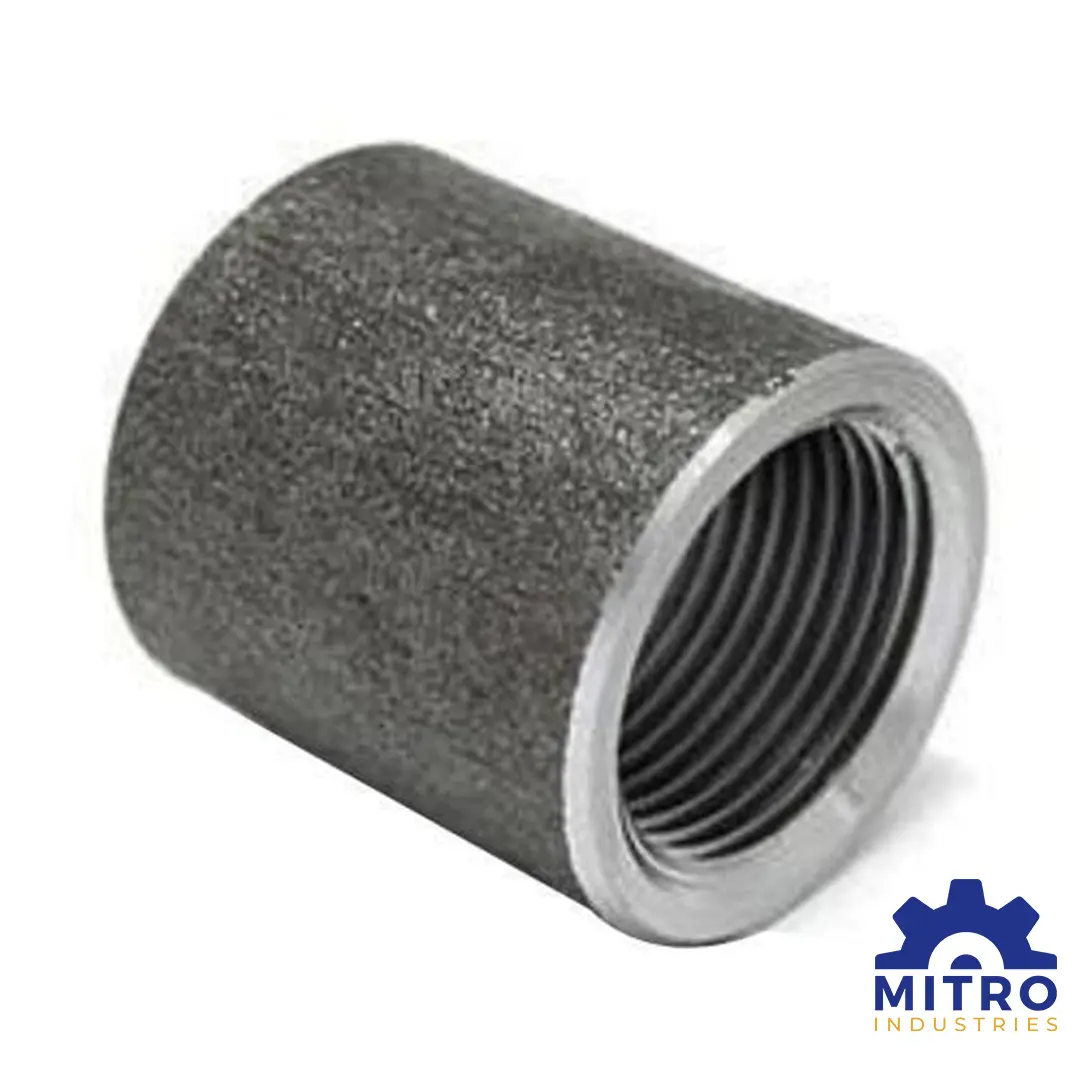

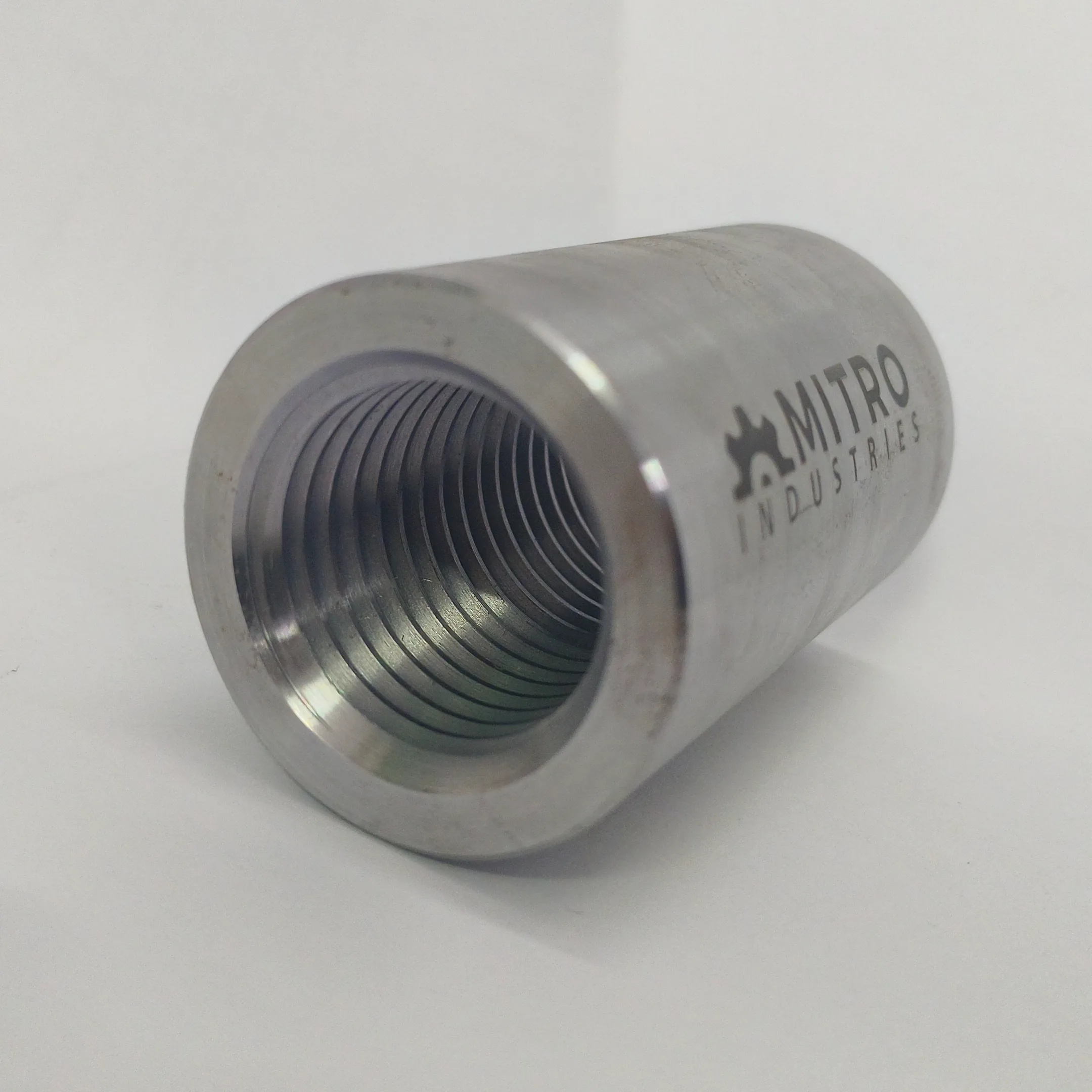

Parallel Rebar Cold Forged Coupler

Reinforcement couplers are used to reinforce the cast-in-situ and element structures of buildings, where the idea is to replace the normal lap joint of the rebar with a coupler that transfers force from the rebar. View Complete Details...

Product Specification

Mitro Rebar Couplers are suitable to join the reinforcement bars end to end. Couplers are an efficient alternative for traditional lap splices or overlapping joints.

Mitro Rebar Couplers are readily available for rebar diameters ranging from 16 mm to 40 mm. We can customize our products to meet your specific requirements.

Our Rebar Cold forged couplers comply with IS 16172 standards and EN8D material. While using this type of coupler, the Cross-section area of the bar is not reduced and it makes a strong structure. We offer quality threading services on-site so that you can install them easily.

Benefits of Rebar Coupler

• Cost Saving

• Higher Ultimate Tensile Test (UTS)

• Shortens project duration

• No torque wrench required

• No Rebar Congestion

• Improvement in concrete flow

With Our Reinforcing Bar Couplers, you will be able to simplify and make it easy for you to install or build reinforced concrete. Our couplers offer precise weight control higher strength and better quality with uniform properties throughout the length. Rebar Couplers, offered by us, are exemplary for their flawless design that allows better concrete flow and consolidation while at the same time reducing rebar congestion. Such a design minimizes reinforcement fixing errors and offers greater flexibility in structuring RCC.

Material - EN 8D

Sizes - 16MM TO 40MM

Features of Rebar Cold Forged Coupler

• Cold Forged couplers are designed and manufactured in compliance with IS 16172.

• There is no reduction in the bar cross-section area

• This is a Full Tension Splice the bar breaks under tensile load.

• Installation of Cold Forged coupler is easy, no torque wrench is required for installation.

• This Coupler is for all splicing requirements (Standard / Position).

There are different code specifications in India for Rebar Coupler which are given below

1. ACI: 318-2008

Type 1: As per this code joint should be required to achieve 1.25Fy as a minimum.

Example:- For Fe500 the tensile strength expected is at least 625 N/mm2.

Type 2: As per this code Joint should be required to meet the 1.25Fy requirement and also meet the Tensile Strength of the rebar.

For Example:- For Fe500 the ultimate stress expected from the same is at least 700 N/mm2.

2. BS 8110-Part 1, Section 3, 1989

In this Code Specification testing of the rebar coupler of a precise type, the permanent elongation after loading to 0.6fy should not exceed 0.1mm.

For Example:- For grade 460 the tensile strength should exceed 497 N/mm2.

3. IS 1786-2008

In this Specification, Fe500 Rebar is considered acceptable for use anywhere in the structure if meets the ultimate strength of 545 N/mm2 which is much less than the 1.25Fy.

In this case, the Condition becomes at least 625 N/mm2 as well.

4. IS 16172-2014

Coupler to be designed for Fe550 grade.

The only tests recommended for acceptance on projects are static tensile tests.

Example:- Fe500 rebar breaking at a stress of 580 N/mm2 is acceptable as per IS 1786 requirement of 545 N/mm2.

Material Used

In this Rebar Coupler EN8D Material Is used which gives high Tensile Strength to the reinforcement joint. In EN8D Material Carbon composition is 0.40-0.45.

Steps for the Installation of Bar Cold Forged Coupler

Step 1

Cutting a TMT Bar

The end of the reinforcing bar is sawn square. The TMT Bar should be cut at 90 degrees at the end of the reinforcement bar.

Step 2

Cold forging of TMT Bar

The sawn end of the reinforcing bar is then enlarged by the cold forging process the core diameter of the bar is increased to a pre-determined diameter.

Step 3

Threading on TMT Bar

Finally, the Rebar threading machine is mechanically cut onto the enlarged end of the bar.

Step 4

Fixing of TMT Bar Coupler

The Rebar coupler is ready to join the TMT Bars

Rebar Cold Forged Coupler Specification

| Bar Diameter (mm) | 12 | 16 | 20 | 25 | 32 | 40 |

| External Diameter (mm) | 20 | 25 | 32 | 40 | 50 | 62 |

| Coupler Length (mm) | 30 | 36 | 44 | 50 | 64 | 80 |

| Thread Size | M14 | M18 | M24 | M29 | M36 | M45 |

| Thread Pitch (mm) | 2.0 | 2.0 | 2.5 | 3.0 | 4.0 | 4.5 |

| Weight (Kg) | 0.04 | 0.05 | 0.15 | 0.28 | 0.53 | 1.00 |

Product related to Rebar Coupler

Find a similar products you may like