PVC Manhole Footstep

Mitro Industries is a top manufacturer and supplier of PVC Manhole Footstep, specifically designed for applications in water wells, overhead water tanks, sewage manholes, and water treatment plants. View Complete Details...

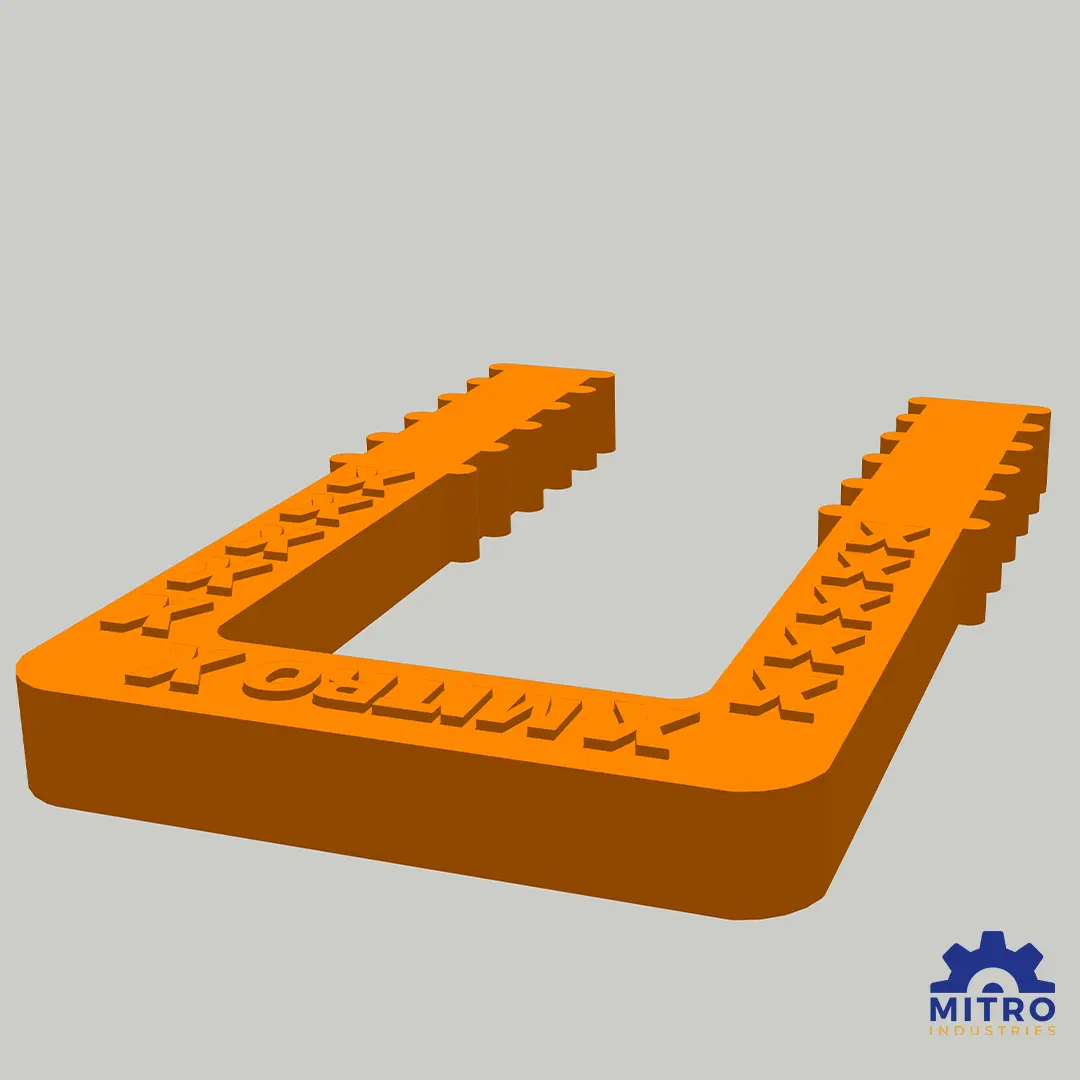

Product Specification

Mitro Industries is a top manufacturer and supplier of PVC Manhole Step, also known as PVC footsteps, specifically designed for applications in water wells, overhead water tanks, sewage manholes, and water treatment plants. These rungs are made using PVC rather than traditional materials like steel or cast iron.

We specialize in producing customized PVC encapsulated rungs using high-quality materials. To enhance safety for workers, our PVC rungs offer a secure grip, ensuring stability while climbing.

Material & Specification

- PVC encapsulated rungs are made with MS rod.

- PVC Footstep available in various sizes, including 8mm, 10mm, and 12mm.

- Manufactured in compliance with IS standards.

- These rungs come in both orange and black colors.

- This Footstep made with high-quality of PVC material.

- The standard size for our PVC rungs is 263 x 164 x 25mm.

Note : We also offer customized PVC Footstep based on specific client requirements to meet different project needs.

PVC Footstep Sizes & Specification

| Sr. No. | Length | Width | Thickness | TMT Bar | Steel IS Code | PP Material |

| 1 | 263 | 165 | 25*23 | 8 mm TMT | As per IS 1786 | Color Black |

| 2 | 263 | 165 | 25*23 | 10 mm TMT | As per IS 1786 | Color Black |

| 3 | 263 | 165 | 25*23 | 12 mm TMT | As per IS 1786 | Color Black |

| 4 | 263 | 165 | 25*23 | 10 mm TMT | As per IS 1786 | Color Orange |

| 5 | 263 | 165 | 25*23 | 12 mm TMT | As per IS 1786 | Color Orange |

| 6 | 375 | 165 | 25*25 | 10 mm TMT | As per IS 1786 | Color Black |

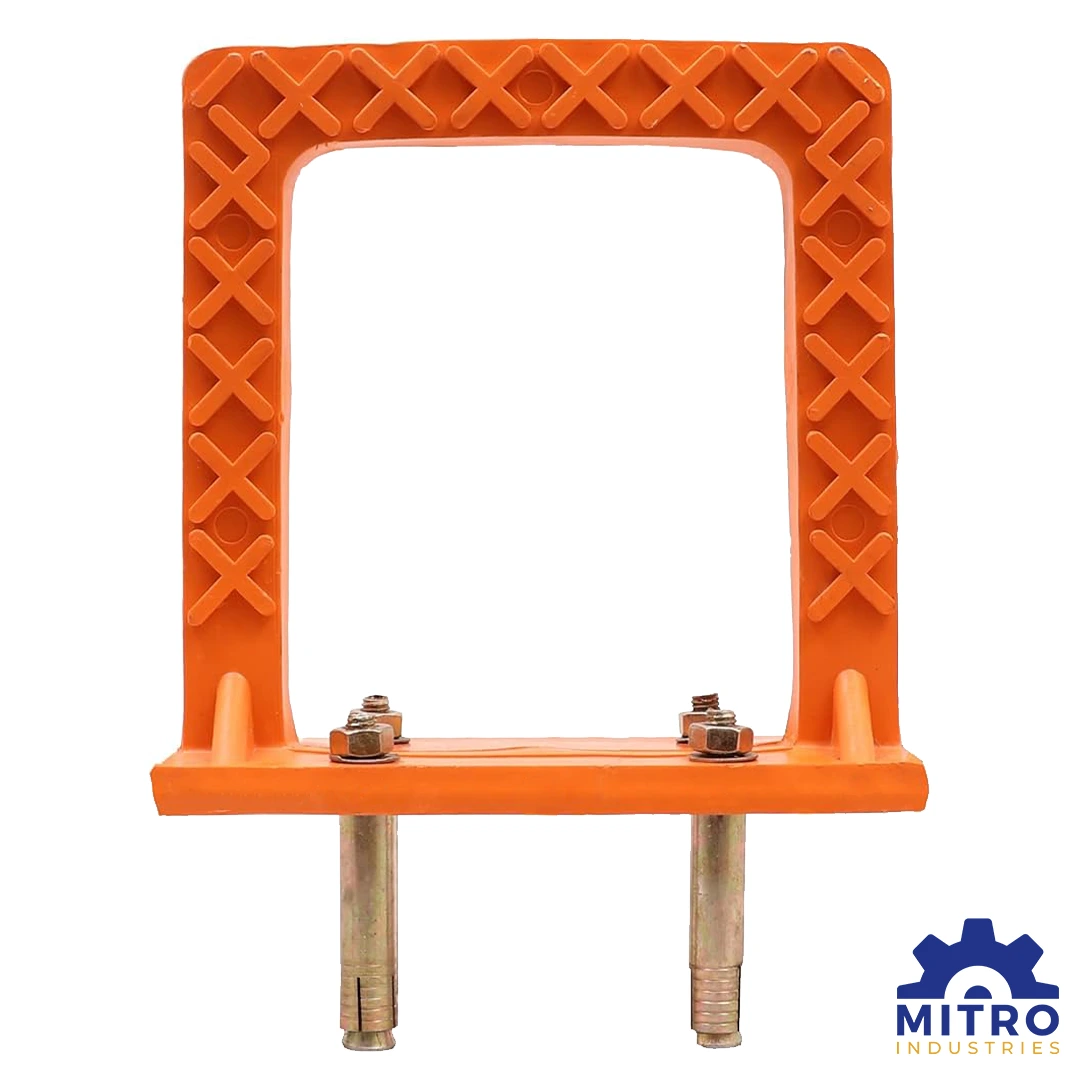

Installation of PVC Footstep

Material Required*

- Bubble level.

- Nylon hammer.

- Any Manhole Footstep.

- Drill bit for concrete of 25 mm diameter.

- Marker pen and meter.

Step 1

Following the bubble level rule, we mark the ends where the rungs will be installed. The distance will vary based on the model.

Step 2

Repeat step 1 for each step. Maintaining a distance of 2350 mm between each step is recommended.

Step 3

Drill the concrete depending on the markings using 25mm diameter drill to a depth of 850mm, creating a precise hole to fit the rungs. Ensure to drill accurately to avoid unintended consequences.

Step 4

Using a hammer, carefully insert the rungs at the designated spots until they are securely in place.

Step 5

Using a hammer, carefully insert the rungs at the designated spots until they are securely in place.

Product related to Construction Safety

Find a similar products you may like